Industrial Burn-Off Ovens are designed for thermal cleaning of metal parts by removing paint, powder coating, epoxy, grease, oil, rubber and other organic residues.

Using controlled high-temperature pyrolysis, these ovens help reduce cleaning costs, extend part service life and improve production efficiency. Multiple heating options are available, including LPG, natural gas, diesel oil and electric heating.

ECOCO Industrial Burn-Off Ovens utilize a controlled burn-off process under negative pressure to decompose organic residues into gas and ash. The process ensures uniform cleaning, high efficiency, and environmental compliance. Compared with chemical stripping or manual cleaning, burn-off ovens significantly reduce labor cost, processing time, and secondary pollution.

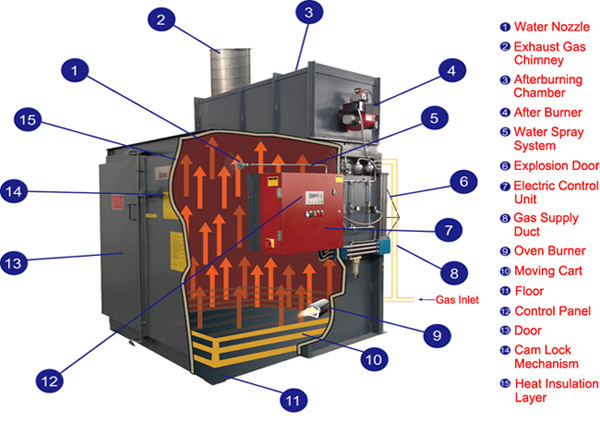

The burn-off oven operates by gradually heating contaminated metal parts inside a sealed chamber. Organic materials are thermally decomposed at controlled temperatures and converted into combustible gases. These gases are then directed to a secondary combustion chamber, where they are fully oxidized at high temperature before being discharged through the exhaust system.

Controlled heating to prevent metal deformation

Negative pressure operation for enhanced safety

Secondary combustion for clean exhaust emissions

Ideal for stripping paint and powder coating from hooks, hangers, frames, racks, and other metal fixtures used in coating lines.

Efficiently removes plastic, rubber, and polymer residues from extrusion dies, filters, screens, and molds without mechanical damage.

Widely used for cleaning engine blocks, cylinder heads, pistons, and other automotive components during remanufacturing and maintenance.

Suitable for cleaning spinnerets, filters, meshes, and metal parts used in chemical fiber and polymer processing industries.

Fully automatic thermal cleaning process

Short cleaning cycle, typically 2–4 hours

Significant reduction in labor and maintenance cost

Siemens touch-screen PLC control

Precise temperature and process control

Automatic safety monitoring and alarms

Negative pressure furnace chamber

Secondary combustion chamber (700–900°C)

Low emissions compliant with environmental regulations

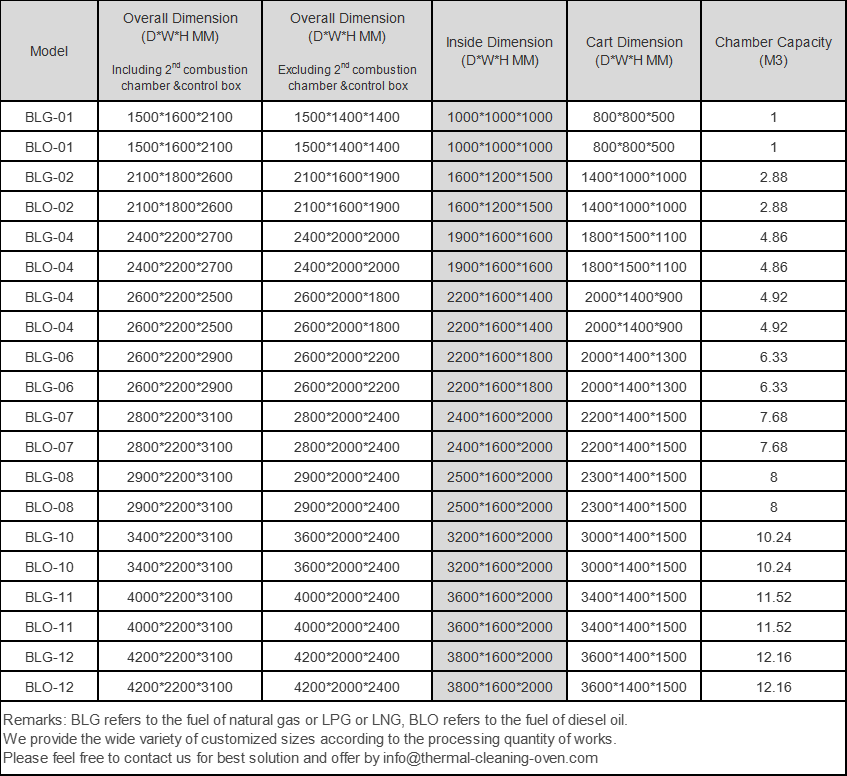

Industrial Burn-Off Ovens are available in multiple chamber sizes and load capacities. All systems can be customized based on customer requirements, including:

Chamber dimensions and maximum load capacity

Maximum operating temperature

Fuel type: natural gas, diesel, or electric heating

After the burn-off process, organic residues are completely removed, leaving only a small amount of inorganic ash. Cleaned metal parts can be reused immediately or proceed directly to recoating, assembly, or further processing.

No. The controlled temperature ramp and uniform heating ensure that metal parts retain their original mechanical properties without deformation.

Paint, powder coating, plastics, polymers, rubber, oils, resins, and other organic materials can be effectively removed using a burn-off oven.

Yes. The system is equipped with a secondary combustion chamber and exhaust treatment, ensuring clean emissions and compliance with environmental standards.

Contact: Alice

Phone:

E-mail: alicexu@ecoco-oven.com

Whatsapp:+86 18151380595

Add: Room 122-2, No.3 Business Building Shengyuan Community, Tinghu District, 224001, Yancheng City, Jiangsu, China

We chat