Burn Off Ovens efficiently strip off powder coating, paint, epoxy, grease, oil, rubber, varnish and other organic contaminants from metal parts or equipment, such as metal jigs, painted hooks or hangers, grids, coated chain links, motor stators and heat exchangers.

Easily remove the old paint for recoating.

No damage for metal parts by thermal cleaning.

Cost-effective and enviromental friendly.

What are burn off ovens?

Burn off ovens, also called heat cleaning ovens are widely used in the coatings, fibers, electric motors and plastics industry. The burn off ovens has two relatively independent heating systems as well as temperature and smog control system. In the first heating system, the fixtures are heated to a set temperature from 250 to 420 celcuis degree without direct flame impingment. In this process, the organic coatings on the surface of fixtures are gradually decomposed into smoke and ash. The smoke generated by the first chamber into the second combustion chamber is fully burned at 600-800 celcuis degree, coverting into water vapor and air, which are discharged into the atmosphere by the exhaust stack.

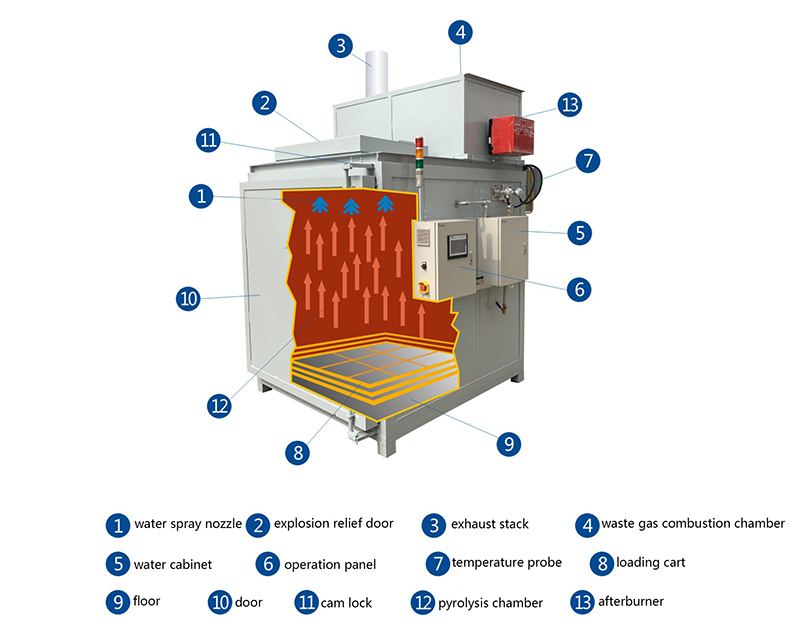

Structures of Burn Off Ovens

Primary Burner heats the working chamber to 427°C. Volatile materials are driven off as smoke into the second combustion chamber. The burner flame is confined to the combustion chamber never touching the parts.

Afterburner operating at 760°C for burning the smoke consuming the pollutants, leaving only invisible, odorless and harmless water vapor and carbon dioxide to exit the exhaust stack.

Explosion Relief Door automatically opens to relieve excess pressure then closes preventing air from reaching combustible materials.

One Touch Control System monitors the combustible vapor in the oven and controls it at a safe level. When starts the oven, the system controls the cycle time automatically according to the volume of organic materials.

Technical Parameter

| Power Supply | 220V 50Hz/60Hz |

| Heating Media | Natural Gas,LNG,LPG,Diesel oil |

| Working Temperature | 0~450 celcuis (adjustable) |

| Fuel Consumption | 10~12m3/hr for NG |

| Cycle Time | 2 hours |

| Control Mode | PLC automatic control system |

| Processing Capacity | 18-30kg/hr (referring to weight of coating) |

| Cart Type | flat or hanger |

| Emission Standard | GB16271-2014 |

Recommended Applications

| Applicable Industry | Type of Removal of Coatings/Parts |

| Motor repair shop | motors, stators |

| Marine NL | motors |

| Paint stripping | hooks, jigs, grids, racks |

| Cleaning industry | hot runners, heat exchangers |

| Paint stripping | cast iron parts, car frames, tubes, pipes |

| Plastic removal | injection molding parts, screws |

| Paint industry | paint |

| Producer of motors | motors |

| Recycling of motors | motors |

| Recycling of reject parts | defective paint |

| Recycling company | scrap iron |

| Producer of office furniture | paint |

| Producer of tyre rims | paint |

| Steel industry | motors |

| Coating industry | teflon |

| Cleaning industry | paint stripping |

| Motor rewinding company | motors |

| Plastic painted parts for automotive | MS jigs |

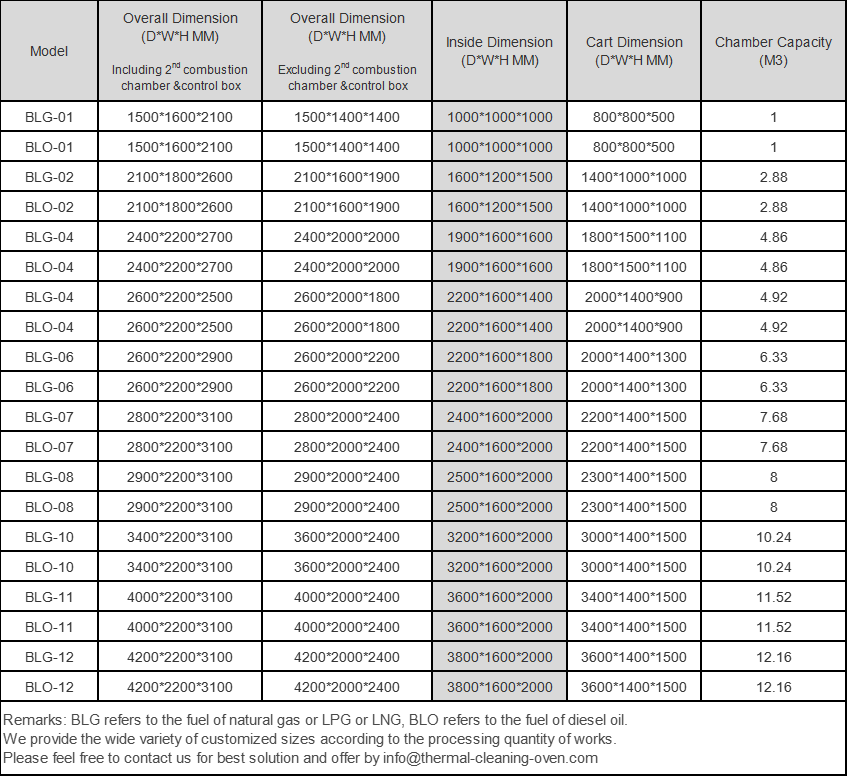

Specifications

Parts before and after processing by burn off oven & burn off oven on site

The coating on the surface of metal parts turns into ash after processed by high temperature in one cycle. Some ash falls on the bottom of the furnace.The remaining ash on the surface of metal parts can be cleaned by tapping lightly or with a water gun.

Contact: Alice

Phone:

E-mail: alicexu@ecoco-oven.com

Whatsapp:+86 18151380595

Add: Room 122-2, No.3 Business Building Shengyuan Community, Tinghu District, 224001, Yancheng City, Jiangsu, China

We chat