vacuum pyrolysis cleaning furnace is to remove polymer from metal parts, such as candle filters, spinnerets, meshes, extrusion screws, breaker plate...etc.

What's the electric pyrolysis cleaning furnace?

Vacuum Cleaning Furnace is suitable for cleaning the polymer materials filters and strainers, making them be reused after calcination, and saving the production cost. It is also a kind of environmental protection equipment. The Vacuum Spinneret Cleaning Furnace applied the characteristics that polymer can be melted at a certain temperature, decomposed under the condiction of high temperature around 300℃ and isolating from air, and complete oxidation when above 400℃ and a little oxygen and certain vacuum degree. Using this characteristics, we first heat the cleaned pieces to the melting temperature, meiting the high polymer on the surface of filters and let them flow down into the waste collecting tank. At this time, surface of the filters remians only a little high polymer and ash content, when the furnace temperature rose up to the cracking temperature ( can according to technological requirements ), open the vacuum pump, lead to a small amount of air to the rest of high polymers, they will be completely oxidation and can get carbon dioxide and water, through the suction of water-ring vacuum pump, the carbon dioxide and water vapour generated in furnace are washed by the spray washer, and then discharged out the furnace. No exhaust gases, smog and ash throughout the working process, just a small number of carbon dioxide, and no more burning is needsd for the exhaust, the water takes away only a small amount of ash.

How does the electric pyrolysis cleaning furnace work?

I. Melting Phase.

The parts to be cleaned are heated to 320°C in the chamber. After this process, most of the polymer melts and drains into the bottom collector.

II. Pyrolysis Phase.

Polymer that did not melt during the first phase will be pyrolyzed and vaporized under vacuum. The generated gases are converted to CO2 and H2O (Vapor) in the catalyst heater.

III. Oxidation Phase.

Remaining polymer that still exist after the pyrolysis phase will be burnt under vacuum and limited air. The generated gases also are converted in the catalyst.

What are the advantages of the electric pyrolysis cleaning furnace?

High thermal efficiency and low consumption

Easy operation and automatic

The metal parts will be cleaned well with smooth wire hole

Temperature raise fast and even inner temperature of furnace

Convenient inspection and maintenance

Environmental protection, energy saving, security and stability

Which applications are the electric pyrolysis cleaning furnace for?

Filter screens / Filter elements

Spinnerets

Spin packs

Non-woven dies

Extrusion screws, screws elements

Blown film die heads

Filter bundles / Filter candles

Breaker plates / screens

Laser Filter Discs

Candle filters

What polymer can be removed by electric pyrolysis cleaning furnace?

Polyolefins: PE, HDPE, PP, PB, EVA, EVOH

Polyesters: PET, PBT, PC, PTT, PEN

Polyamides: PA6, PA6.6, PA12, PPA

Polystyrenes: PS, ABS, SB, SBS, SAN

How to get a suitable model for you?

Tell us what metal part will you clean

The quantity of metal part to be cleaned at one time

Tell us what polymer to be removed

According to the your requirement, we will advise the most suitable size for you.

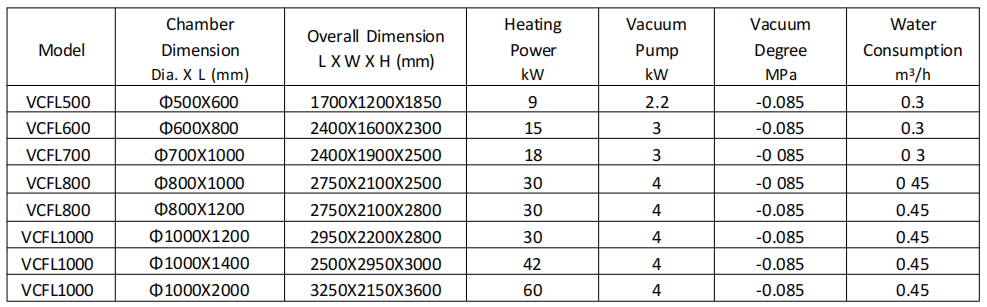

Standard model size

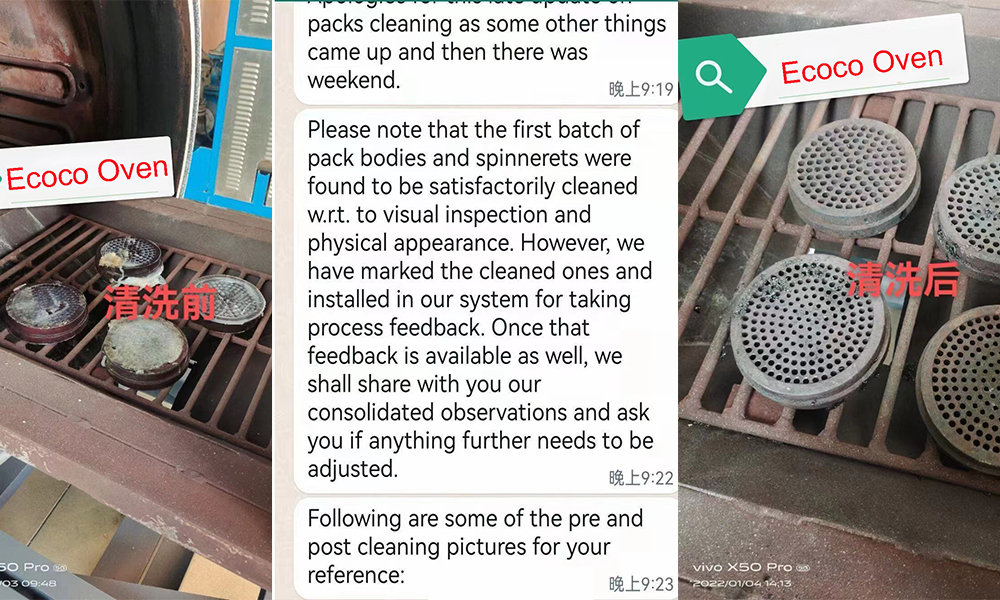

From the customer's feedback

Contact: Alice

Phone:

E-mail: alicexu@ecoco-oven.com

Whatsapp:+86 18151380595

Add: Room 122-2, No.3 Business Building Shengyuan Community, Tinghu District, 224001, Yancheng City, Jiangsu, China

We chat